The flanged pipe still represents the most efficient and reliable means for conveyance above the ground level, horizontally or vertically, of fluids and gases under pressure, thanks to a high torsional and tensile strength, resistance to pressure fluctuations and the lack of points of vulnerability due to the reduction of the pipe thickness.

“Two pipes connected to each other via a flanged connection form the so-called flanged joint.”

This is ensured first of all by the material used for the pipes, i.e. steel, which has high strength, resistance to stress and corrosion, and secondly by the type of connection used to interconnect the pipes with each other or with accessories, i.e. the flanged connection.

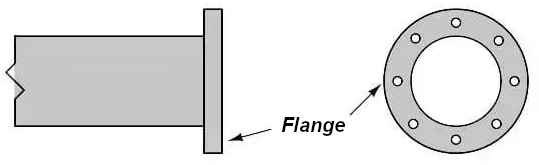

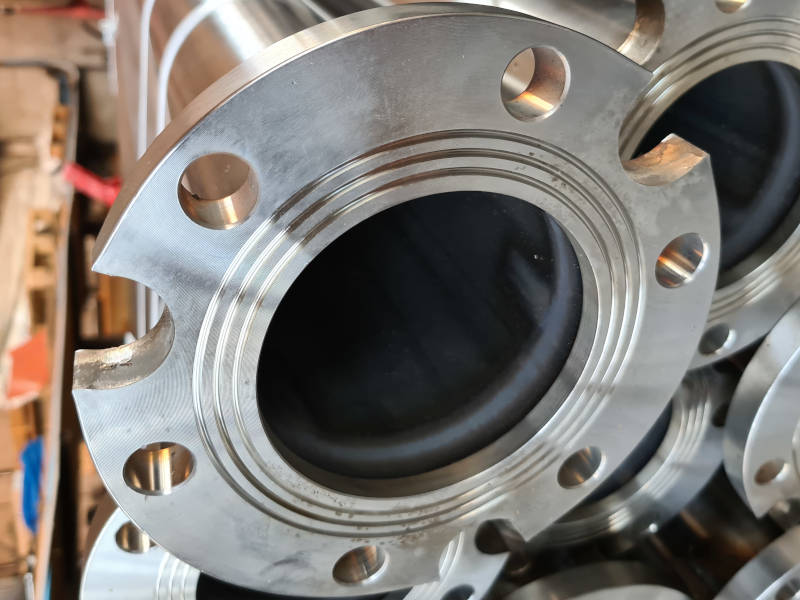

A flange is a metal ring welded to the ends of the flanged pipe that allows a rigid connection between them. It has several holes parallel to the center of the tube, which can accept bolts for tightening (see figure).

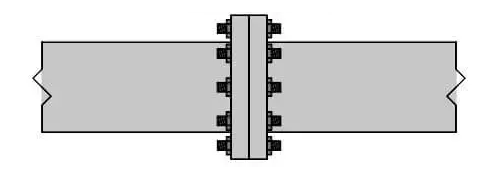

Two pipes connected to each other via a flanged connection form the so-called “flanged joint“, a very solid joint system, capable of withstanding high pressures.

The flanged connection is made pressure-tight by inserting a donut-shaped gasket between the flanges, before tightening the bolts. Gaskets are typically made of softer materials than flanges. Positioned between the flanges, the gasket is tightened together them to seal any pressure loss. Furthermore, the thickness of the gasket creates a sort of opening between the pair of flanges, called “gap”.

Pressure tightness is also ensured by the design of the flanges, which can be of different types. For example, the most common ones have a series of concentric grooves on the faces in contact with the gasket. They form a sealing surface with a greater leakage path than if the faces were smooth, discouraging leakage of fluid under pressure.

The use of flanges also has another advantage: their insertion does not involve a reduction in the thickness of the pipe, which is therefore uniform along its entire length, making the flanged joint a structure free of points of vulnerability.

The flanged joint does not require any special equipment for its assembly, other than following certain procedures dictated by common sense, such as aligning the flanges perfectly before tightening, and tightening the bolts diametrically opposed to each other, so as to distribute the pressure on the gasket. At this link we have described an accurate installation procedure for flanged pipes, which we recommend taking a look at.

“The flanged joint is definitely one of the best interconnection methods in the hydraulic, agricultural and industrial fields.”

Ultimately, the flanged joint represents an excellent method of interconnection between pipes, which makes the flanged pipes reliable and capable of withstanding high pressures, therefore being mounted at great depths.

In Irritecnica, producing and selling flanged pipes for more than 30 years, we have understood how the customer first of all wants a solid, reliable and long-lasting product, which allows him to serve his needs without worries, so we can confirm how the flanged joint is definitely one of the best interconnection methods in the hydraulic, agricultural and industrial fields.