Flanged pipes advantages

Home | Advantages

Reliability

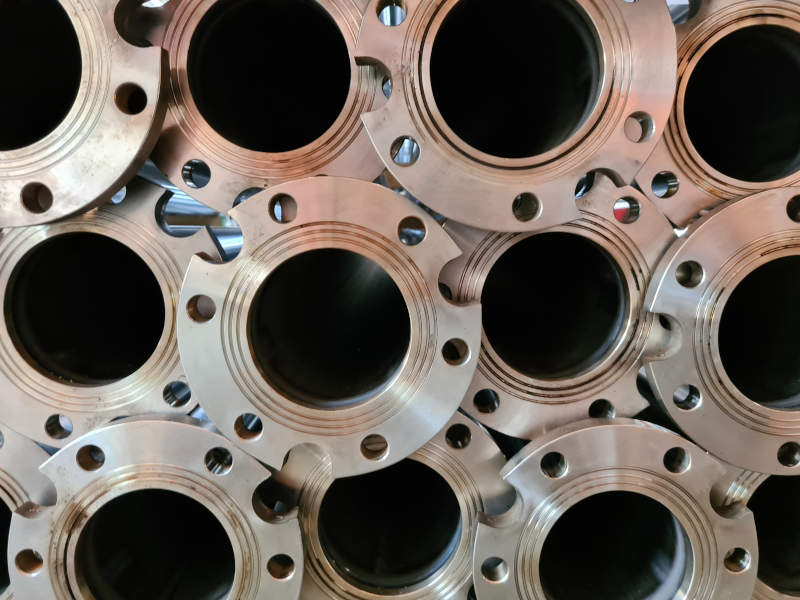

TORSIONAL AND TENSILE STRENGTH

The carbon steel or AISI 304 or 316 stainless steel flanged pipes have a high resistance to traction, torsion and shocks, making them a very reliable means of transport for liquids and gases.

They are used above all as vertical pipelines, as they optimally withstand the torsional force due to the switching on of the electric pump, the vibrations produced during its operation and water hammers.

Anti-corrosion

AND RESISTANCE TO RUST

Corrosion is an irreversible process of degradation of the characteristics of a material to which all objects exposed to atmospheric agents or placed in the ground are subjected.

Thanks to the use of AISI 304 or 316 type stainless steel or carbon steel with special galvanization or painting, the flanged pipes have proven resistance to a wide range of atmospheric, chemical, textile, oil and food exposures and high durability over time.

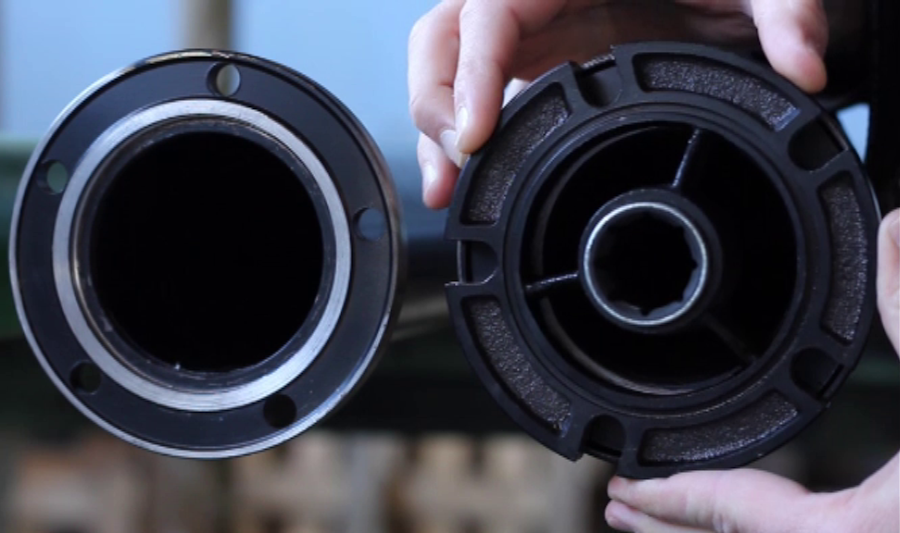

EASE OF ASSEMBLY

Installation

The flanged pipes have the characteristic of being easy to install, as no special equipment or particular preparation is required and the maintenance required is almost zero.

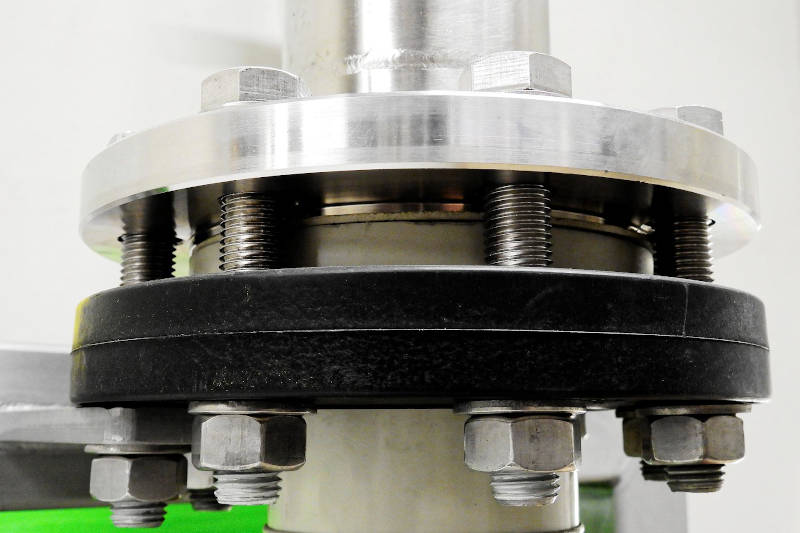

Pressure tight

AND ANY ITS FLUCTUATION

The flanged connection guarantees excellent pressure resistance and safety against any pressure fluctuations.

Pressure sealing is achieved by inserting a donut-shaped gasket between the flanges, before tightening the bolts. Gaskets are typically made of softer materials than flanges.

Design of flanges

IT GUARANTEES THE PRESSURE-TIGHT

Pressure tightness is also ensured by the design of the flanges, which can be of different types. For example, the most common ones have a series of concentric grooves on the faces in contact with the gasket.

They form a sealing surface with a greater leakage path than if the faces were smooth, discouraging leakage of fluid under pressure.

Eco-sustainability

Compared to pipes made with plastic materials, such as PVC or polypropylene, flanged pipes are eco-sustainable and have a low environmental impact. By using flanged pipes you do nature a favor by avoiding:

Microplastics

They can spread during the normal transport of liquids in deteriorated pipes

Abandon in nature

Abandonment of plastic pipes in the environment once reached their end of life

Disposal

Plastic pipes must be properly disposed of or recycled by law

Uniformity

OF THE PIPE THICKNESS

The flanged pipes are very robust also due to the fact that their thickness is uniform along the entire length of the pipe. In fact, the insertion of the flanges does not lead to a reduction in the thickness of the tube, making the structure free of points of vulnerability.

Reduced costs

MANAGEMENT AND TRANSPORT

Given their rigidity and robustness of construction, the flanged pipes do not risk breakage during transport and handling, or in the event of sudden impacts and accidental damage. This minimizes running costs.

They are also resistant to the stresses that may be subjected to during their installation.

Flangedpipes.com

Flangedpipes.com is an idea by Irritecnica, which aims to create a reference site for flanged steel pipes for all types of applications.