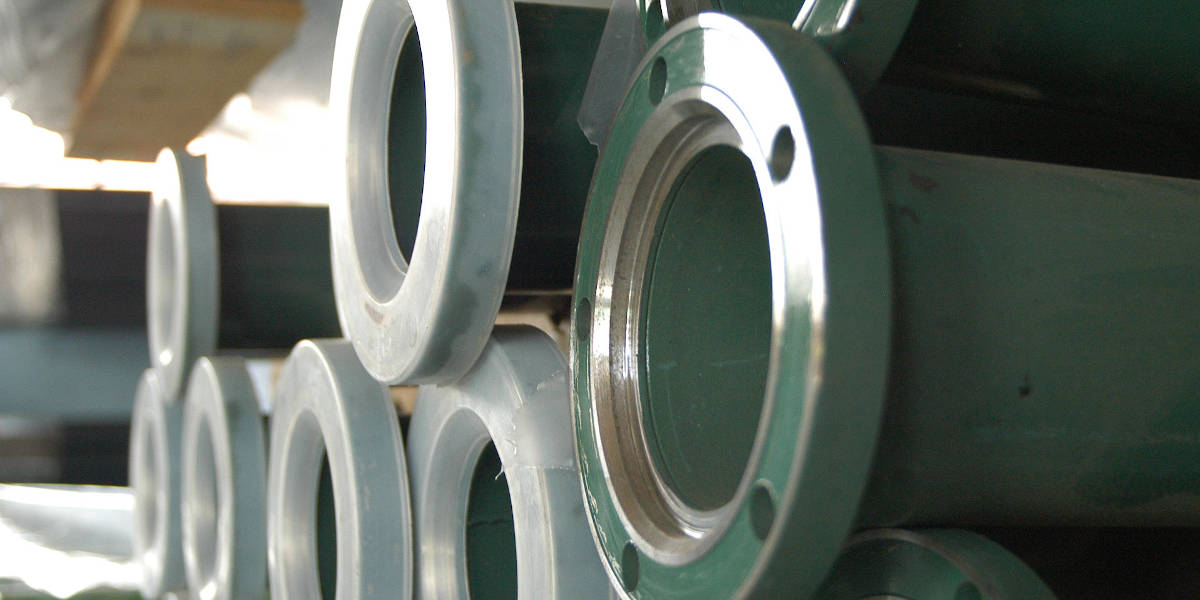

The flanged connection, as shown on this page, presents a whole series of advantages, which combined with the advantages of the material used for the pipes, such as carbon steel or AISI 304 or 316 stainless steel, provide connection reliability, tensile and impact strength, resistance to pressure and its fluctuations, thickness uniformity and lack of points of vulnerability, and so on.

“Another fundamental aspect to take into account is the ease and practicality of assembling the pipes that use the flanged connection.”

These characteristics of the flanged joint are not the only reason for the massive and growing adoption in all fields of industrial, agricultural and water supply systems. Another fundamental aspect to take into account is the ease and practicality of assembling the pipes that use this connection. In fact, the flanged pipes have the characteristic of being easy to install, as no special equipment or particular preparation is required and the maintenance required is almost zero.

Below is a useful procedure to follow to install a flanged pipe in a solid and reliable manner.

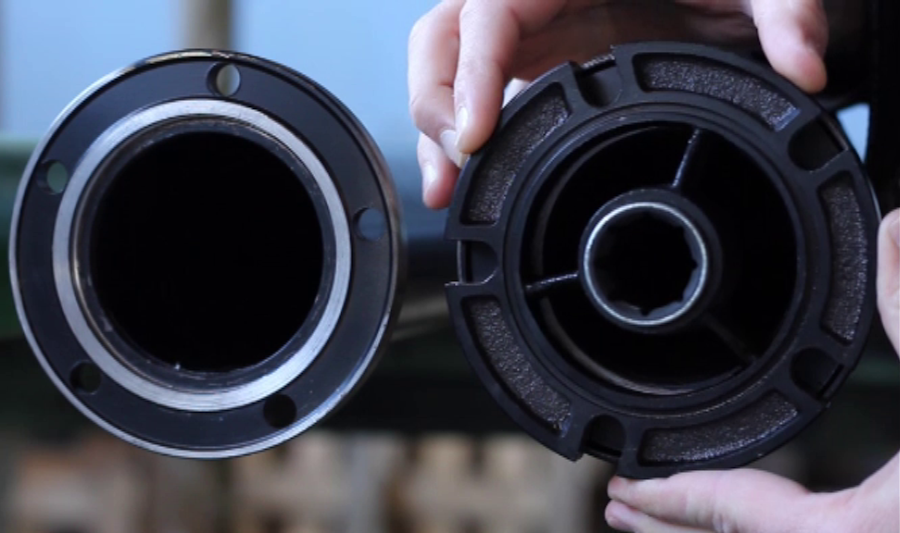

- The first advice to follow is to carefully clean the faces of the flanges, to remove any dirt and rust.

- As a second step it is necessary to precisely align the flanges of the pipes to be connected.

- At this point it is needed to position the gasket, typically donut-shaped with a thickness of at least 3 mm.

- Carefully lubricate the bolts threads to use, as well as all coupling surfaces and flanges.

- Insert the bolts one by one.

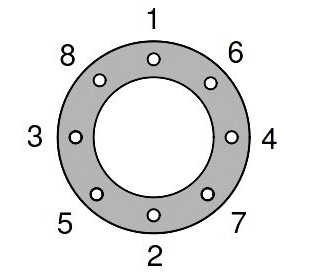

- Tighten the bolts diametrically opposed to each other.

- Finally, tighten all bolts to 100% of the required torque.

A common trick for installing the gasket is to first insert only half of the bolts at the bottom of the flange, slide the gasket into the pair of flanges, and insert the other half of bolts, then proceed to tighten them to the desired torque.

An important procedure to observe when tightening the bolts is to distribute the pressure, such that no region of the gasket is subjected to a greater pressure than the others. This is achieved by tightening the bolts alternately, tightening the pair of diametrically opposed bolts first to form a cross (top-bottom and right-left) and then an X (see figure).

Definitely, this is the correct procedure for connecting the flanged pipes, which will allow us to have a solid, long-lasting and reliable joint.